A PROTOTYPE ENGINE TO GET YOUR BRAIN CHALLENGE

The basic design of the four-stroke piston engine that powers all of our cars has been kicking around for about 150 years. And during that time there have been countless alternatives proposed. But apart from the occasional oddball-like the Wankel rotary-modern engines, while certainly refined, still stick to the basic formula. Now with ever-increasing demand for greater efficiency, new and older alternative engine designs are attracting attention. We've featured six we've recently come across, but heed one caveat: The people behind these designs make some heady claims that are awfully difficult to confirm at this stage. So keep that in mind when you read a "50 percent fuel economy improvement." We do know that there's plenty of creativity among the world's tinkerers and engineering firms, and one of these may make it under a car's hood. Even if not, who knows where these ideas might lead.

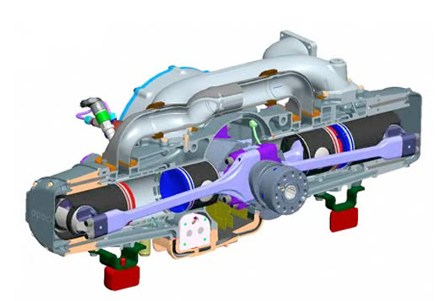

Ecomotors Opposed Piston-Opposed Cylinder (OPOC)How it Works:

The Ecomotors OPOC engine has been in development for about seven years and was originally part of a DARPA initiative to shrink the military ground vehicle powertrain packages.

Now Ecomotors is retooling the concept to work as a clean-burning and efficient option for the civilian market.

The engine is a two-stroke, horizontally opposed, twin-bore, four-piston engine-basically two engines worth of pistons stuffed into one engine's worth of cylinders.

The inner set of pistons work in much the same way a traditional reciprocating-piston engine does. The outside set of pistons is attached to the crankshaft via long, titanium connecting rods tied to a hefty bearing at the back of the piston.

These outside pistons mirror the motion of the inner piston, moving toward the crankshaft as the inner piston moves away from it.

Intake and exhaust are done similarly to a two-stroke diesel-an external air-charger (be it supercharger or turbocharger) forces air into the cylinder through ports in one side of the cylinder sleeve.

As the pistons move the ports are covered up, the air is compressed between the two pistons, fuel is directly injected and the mix can be fired by spark or compression ignition.

Exhaust is eliminated through ports on the other side of the cylinder bore when they are uncovered at the end of the piston travel.

Claimed Benefits: Because the combustion event occurs in the middle of the cylinder bore between two movable pistons, there is more surface area for the combustion pressure to effect,

therefore more of the energy is converted to mechanical force. As a result, the engine's power density is much higher than a traditional engine.

It's also lighter, compact, operates with a simplified intake system and doesn't require the complexity of a separate head.

Status:

Ecomotors has had a lot of success marketing its engines to the military as auxilary power units for in-the-field applications. In the automotive sector it could find many friends as long as it meets emissions requirements.

The small size and high power density lends itself well to the increasingly demanding automotive sector.