- GD&T

GENERAL DIMENSIONING- International Paper Size Standards

- Technical Drawing Styles

- ISO And ANSI Projections

- ANSI Technical Drawing Views

- Technical Drawing Dimesioning Types

- ANSI and ISO Geometric Tolerancing Symbols

- Geometric Tolerancing Reading

- Taylor Principle Rule#1

- Form Tolerances

- Profile Tolerances

- Orientation Tolerances

- Location Tolerances

- Runout Tolerances

- TOLERANCES

ANSI AND ISO- Tolerancing and Engineering Standards

- Hole and Shaft Basis Limits And Fits

- ISO International System For Limits And Fits

- International Tolerance Grade (IT)

- Fundamental Deviations For Hole and Shaft Basis

- ISO Tolerance Band IT01-IT16

- Calculation Of International Tolerance

- Calculation of Upper and Lower Deviation For Shaft

- Calculation of Upper and Lower Deviation For Holes

- ISO Shaft Tolerances (3mm-400mm)

- ISO Shaft Tolerances (400mm-3150mm)

- ISO Hole Tolerances (3mm-400mm)

- ISO Hole Tolerances (400mm-3150mm)

- ANSI Standard Limits and Fits

- METAL CUTTING TECHNOLOGIES

- Terms and Definitions of the Cutting Tools

- Cutting Tool Materials

- Selection of Carbide to machine the work-part

- Identification System For Indexable Inserts

- Work-Part Materials

- Machinability and the specific cutting force

- Machinability of the Certain Material Evaluations

- Cutting Forces and Chip Formations

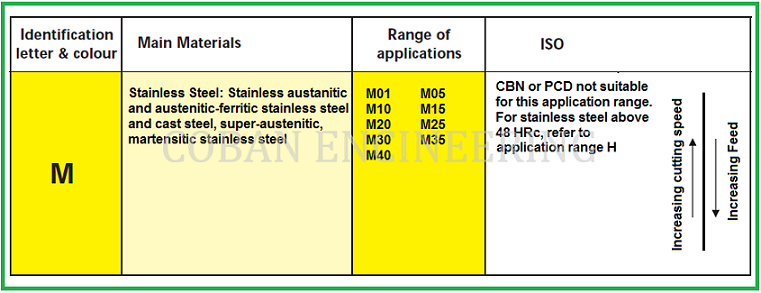

ISO - M :

Stainless steels are materials alloyed with a minimum of 12% chromium; other alloys may include nickel and molybdenum. Different conditions, such as ferritic, martensitic, austenitic and austenitic-ferritic (duplex), create a large family. A commonality among all these types is that the cutting edges are exposed to a great deal of heat, notch wear and built-up edge. Group M includes austenitic stainless steels, austenitic/ferritic steels and cast steels, manganese steel, alloy cast iron, malleable iron. The group is subdivided into the application groups 01-40, dependent on the cutting load.

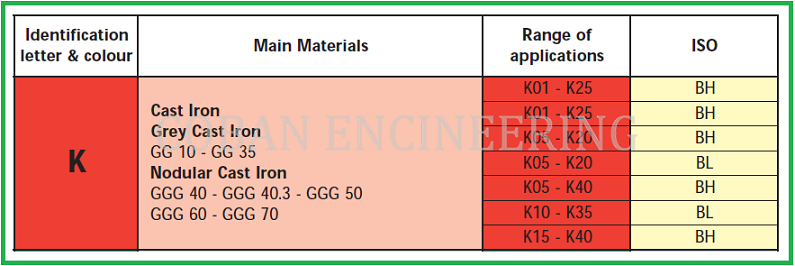

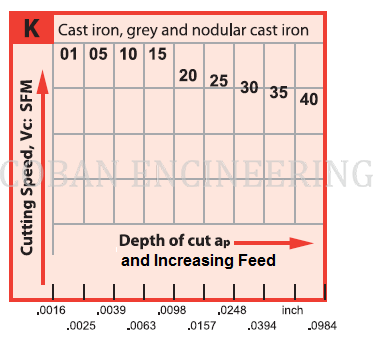

ISO - K:

Cast iron is, contrary to steel, a short-chipping type of material. Grey cast irons (GCI) and malleable cast irons (MCI) are quite easy to machine, while nodular cast irons (NCI), compact cast irons (CGI) and austempered cast irons (ADI) are more difficult. All cast irons contain SiC, which is very abrasive to the cutting edge. Group K incorporates all forms of grey cast iron and malleable cast iron. Dependent on cutting load it is subdivided into the application groups 01-40.

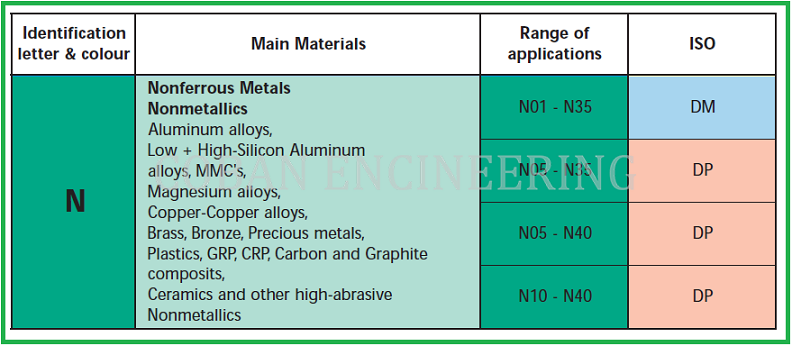

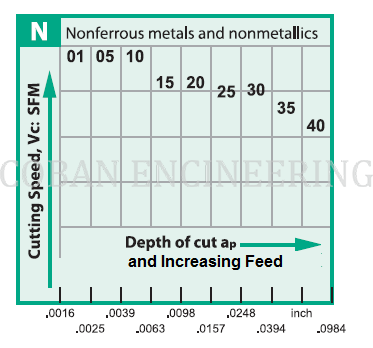

ISO - N :

Non-ferrous metals are softer metals, such as aluminum, copper, brass etc. Aluminum with an Si-content of 13% is very abrasive. Generally high cutting speeds and long tool life can be expected for inserts with sharp edges. This group includes non-ferrous metals, especially aluminum-alloys and non-metal materials. It is, depending on the cutting load, divided into the application groups 01-30.

Copyright ©2010-2023 Coban Engineering.All Rights Reserved.